Sustainable Lithium Battery Recycling

The sustainable processing and extraction of critical minerals from li-ion batteries.

Types of Lithium Batteries We Recycle

We specialise in handling all types of lithium batteries, ensuring their safe and efficient management when they reach their end-of-life. Whether it’s individual cells, modules, complex high-voltage packs, or battery production scrap, we have the expertise and resources to treat and sustainable recycle all types of li-ion batteries.

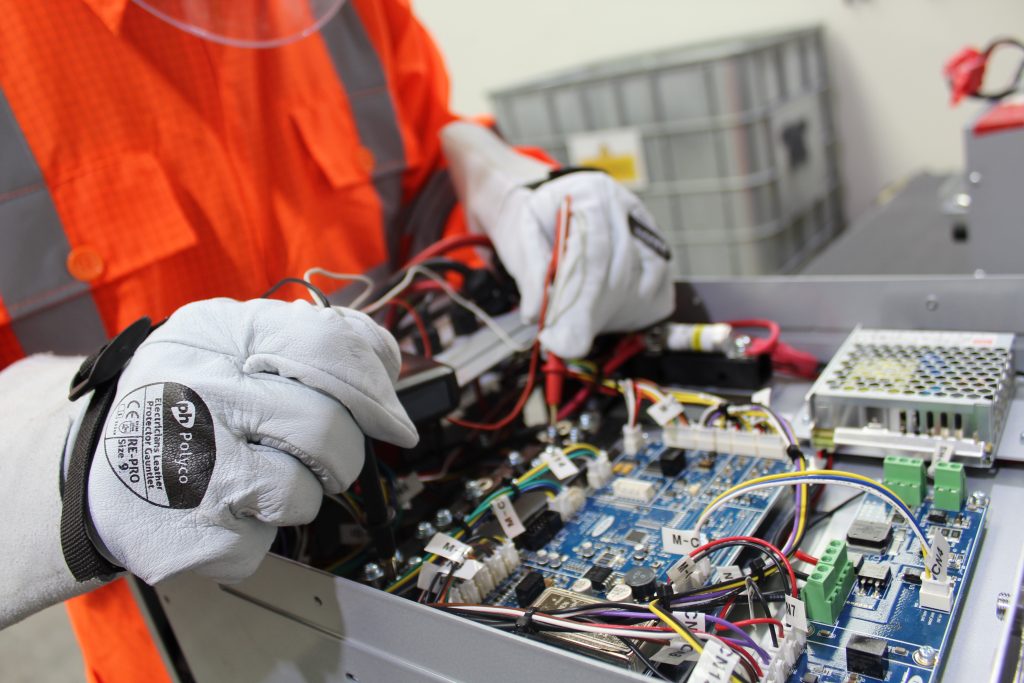

Our team of technicians are fully equipped to test, discharge and dismantle all types of HV packs.

Regardless of application or condition, we have a sustainable solution for all types of modules.

We can handle any and all types of lithium battery cells regardless of form factor, size or chemistry.

A sustainable recycling route for anode and cathode material from throughout the production line.

Our Lithium Battery Recycling Process

We specialise in handling all types of lithium batteries, ensuring their safe and efficient management when they reach their end-of-life. Whether it’s individual cells, modules, complex high-voltage packs, or battery production scrap, we have the expertise and resources to recycle them all.

Testing and Discharging

At Cellcycle, we deliver precise testing and discharging services for lithium battery packs, modules, and cells as part of our comprehensive lithium battery recycling process. Each asset is meticulously analysed and graded to determine its potential for reuse. Batteries deemed unsuitable for reuse are then carefully dismantled and prepared for material processing, ensuring the safe recovery of valuable resources.

In addition, we provide clients with detailed reports on critical metrics, including the State of Health (SoH), State of Charge (SoC), and Root Cause Analysis (RCA) of their lithium battery assets. These insights offer a thorough understanding of battery performance and condition, supporting well-informed decisions in asset management and optimising the recycling process.

All assets are tracked from the moment they leave your site to the point they arrive at ours. All assets are cross-checked and accounted for upon arrival at our facility.

Battery Triage and Dismantling

If required, we can generate comprehensive reports and conduct failure mode analysis to identify potential internal faults that contributed to the battery reaching its end of life. These optional insights provide clients with valuable information on asset condition and lifecycle, supporting informed decisions and promoting responsible lithium battery recycling.

Onsite Support

For clients with specific requirements we can provide on-site triage solutions

Mechanical Separation and Shredding

The next critical stage in our lithium battery recycling process is the shredding and mechanical separation of the battery. This phase involves the safe and controlled shredding of battery cells and modules, conducted by our specialised equipment to ensure compliance with safety regulations.

Following this, the core materials of the battery are mechanically separated with key components such as plastics, polymers, metals like steel, and the electrolyte are isolated during this process.

Recovery and Extraction of Critical Materials

At Cellcycle, we sustainably and efficiently recover a wide range of critical minerals from end-of-life lithium batteries through a combination of in-house processes and those of our government-approved refining partners. These processes are designed to maximise material recovery while minimising environmental impact.

Our Plans for the Future of Battery Recycling

IN partnership with Coventry University and proudly supported by Innovate UK, we are developing and scaling-up the world’s first commercial bio-based recycling solution for

Certifications