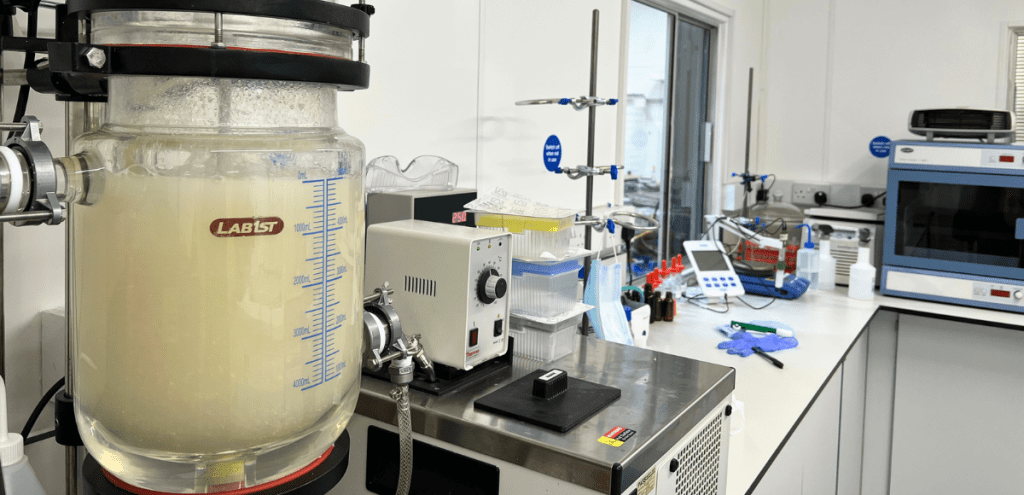

At Cellcycle, we are committed to pushing the boundaries of innovation in lithium battery recycling. This week, our team achieved a major breakthrough in our research and development efforts. Using our novel LithiumCycle™ process, we successfully produced a leachate from which we carried out the selective extraction of nickel and cobalt, achieving a recovery rate exceeding 90%.

Through advanced bioleaching experiments, using acidophilic bacteria, we have been able to generate leachates from various NMC chemistries, including 111, 532, and 811. These leachates, containing nickel and manganese at varying concentrations, were then processed to achieve the efficient and selective recovery of cobalt and nickel, demonstrating the potential for optimised metal recovery from end-of-life lithium batteries.

This achievement represents a significant step forward in our mission to develop sustainable and environmentally friendly lithium battery recycling methods. LithiumCycle™, a process that utilises microorganisms to recover valuable metals from spent batteries, holds the potential to revolutionise the way the industry approaches lithium battery recycling. Unlike traditional methods that rely on high-temperature smelting or harsh chemical treatments, bioleaching offers a low-energy and eco-friendly alternative, aligning perfectly with the principles of the circular economy.

Why Cobalt and Nickel Matter

Cobalt and nickel are essential components in the production of lithium-ion batteries, which power everything from electric vehicles to renewable energy storage systems. Cobalt, in particular, plays a critical role as it enhances the energy density and stability of lithium-ion batteries, making it indispensable for high-performance applications such as electric vehicles (EVs). Nickel, on the other hand, is increasingly being used in cathode chemistries due to its ability to deliver higher energy capacity and reduce the reliance on cobalt, whose supply is limited and geographically concentrated.

Globally, the demand for cobalt and nickel is projected to grow exponentially, driven by the rapid adoption of EVs and renewable energy storage solutions. According to recent market reports, the global cobalt market is expected to reach over $16 billion by 2030, with the nickel market following a similar trajectory as the EV sector expands. However, the mining of cobalt, predominantly sourced from the Democratic Republic of Congo, raises significant ethical concerns related to human rights abuses and environmental degradation. Nickel mining, while more geographically diverse, is not without its environmental challenges, including habitat destruction and high carbon emissions.

By recovering cobalt and nickel from end-of-life lithium batteries through LithiumCycle™, we address multiple challenges: reducing dependence on environmentally harmful mining practices, mitigating geopolitical risks associated with critical mineral supply chains, and contributing to the creation of a circular economy. These efforts not only support the global transition to sustainable energy systems but also enhance resource security for battery manufacturers, strengthening the lithium battery recycling infrastructure worldwide.

The Road Ahead

While we are thrilled with this week’s results, we recognise that there is still work to be done. Further research and experimentation will be conducted to optimise the LithiumCycle™ process, ensuring it is scalable and commercially viable. Our focus will remain on refining these methods to maximise efficiency while maintaining our commitment to sustainability.

These results are a crucial part of our Knowledge Transfer Partnership (KTP) with Coventry University and bring us one step closer to our end goal: to develop a sustainable, closed-loop recycling process for lithium batteries in the UK. Our partnership with Coventry University has been instrumental in advancing our bioleaching capabilities, and we look forward to continuing this fruitful collaboration to strengthen lithium battery recycling practices.

Join Us on the Journey

At Cellcycle, innovation is not just a goal; it is a responsibility. As we continue to explore and implement groundbreaking lithium battery recycling technologies, we invite you to join us on this journey. Together, we can create a future where batteries are not just used and discarded but become part of a closed-loop system that benefits both the planet and the economy.

Stay tuned for more updates as we advance our research and bring sustainable lithium battery recycling solutions to life. To learn more about our work and how we are shaping the future of lithium battery recycling, visit our website or connect with us on our social media channels.